Product released

- Title

-

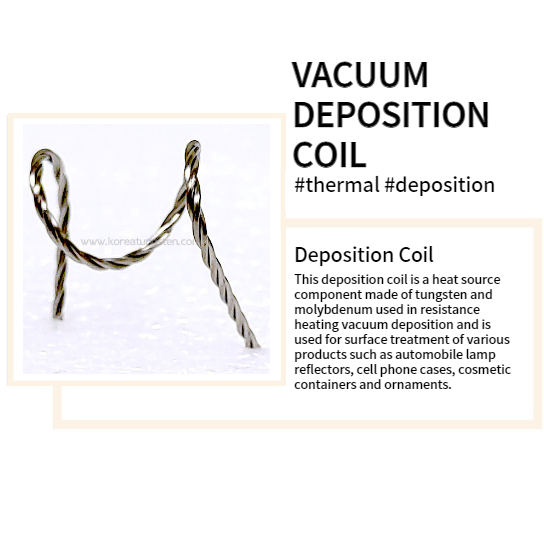

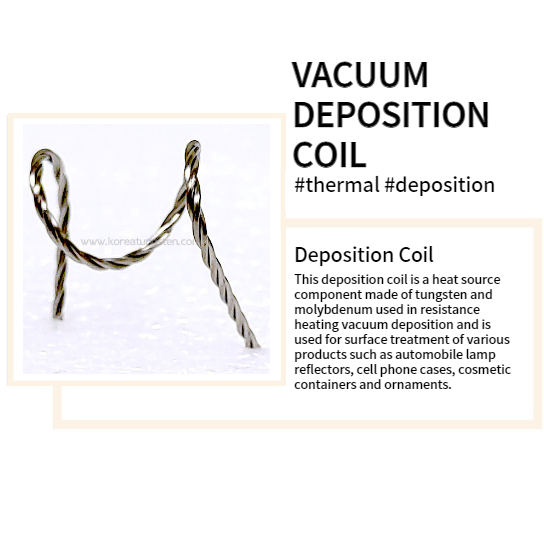

Vacuum Deposition Coil / Heat Source Component - Surface Treatment

- Date

- 2022.04.05

- Attachment0

- Like

- 1

- View

- 100

Contents

In addition to the coil type, resistance heating deposition that heats parts in the form of boats is common,

Hi everyone, this is Innomt

Overseas department of Korea Tungsten: 1st-Gen customized metalwork solution company.

We use high-purity tungsten and molybdenum materials to process necessary parts for equipment such as

semiconductor process, display process, vacuum deposition, etc. and have tantalum, aluminum, tin wire, etc.

This processing product is a vacuum deposition coil made of high purity tungsten material.

The deposition coil is a heat source component made of tungsten and

molybdenum used in resistance heating vacuum deposition and is used for surface treatment of various products

such as automobile lamp reflectors, cell phone cases, cosmetic containers and ornaments.

Also known as thermal deposition as one of the thin film manufacturing methods,

it is a method of manufacturing a film by

heating and evaporating a thin film material in a vacuum and attaching the vapor to a substrate.

In addition to the coil type, resistance heating deposition that heats parts in the form of boats is common,

but electron beam deposition is also used for high melting point materials such as tantalum and molybdenum.

There are also arc deposition and laser deposition.

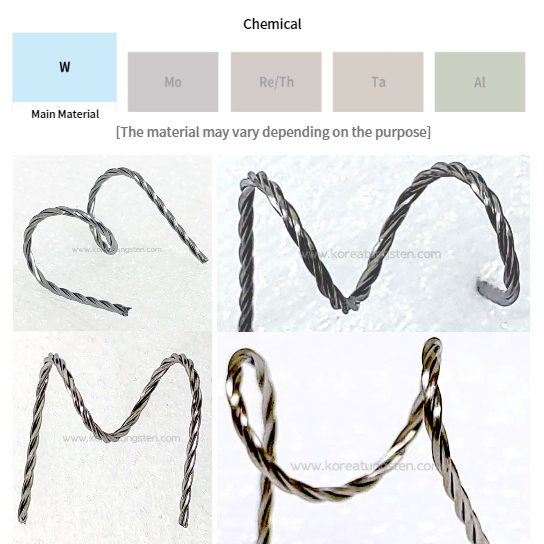

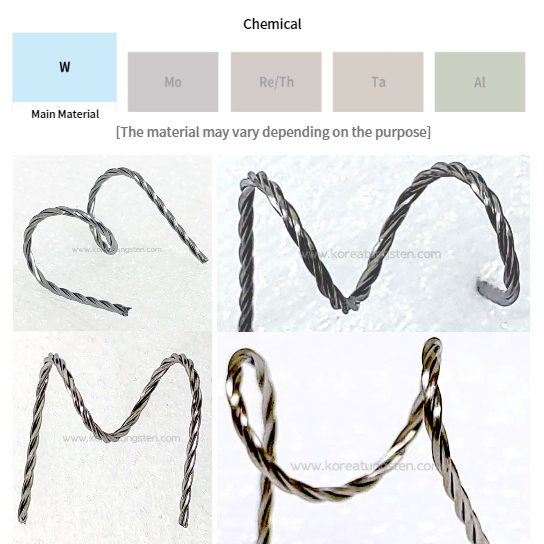

There are many types of parts used in vacuum deposition,

but this product looks a little smaller than usual.

Our products use high-quality and uniform raw materials and have a long lifespan and excellent deposition quality.

In addition, we can respond to various types of products according to your request,

so if you contact us with samples or drawings, you can get a faster response

Thank you.

INNOMT CO., LTD.

TEL. +82-31-815-5522

customer@innomt.co.kr

#value #added #custom #precision #product #korea #tungsten #innomt

#factory #manufacture #metalwork #customizable #deposition #high #purity #coil #vacuum

#heat #Source #component #Thermal #surface #treatment

1

0

게시물수정

게시물 수정을 위해 비밀번호를 입력해주세요.

댓글삭제게시물삭제

게시물 삭제를 위해 비밀번호를 입력해주세요.